What is in our watch strap?

Not all 'NATO' style watch straps are made the same. Phoenix Straps is a premier military strap designer and manufacturer, making watch straps to the exacting standards of Britain's Armed Forces.

A Brief Lesson In History

1938

As the spectre of war loomed over Europe, the British Ministry of Defence faced a surge in demand for equipment, tools, and materials. The concept of standardized military-issued watches was still unfamiliar, with most service members relying on personally purchased timepieces.

The proliferation of privately purchased watches led to a wide disparity in material quality. Pilots, in particular, needed a consistent method of securing their timepieces. In response to this need a dependable supplier of standardized military watch straps was needed.

Standardization

The 6B/159 - With the unreliability of many privately purchased timepieces becoming a critical issue, the Ministry of Defence issued a call for watchmakers to create a robust, standardized timepiece for RAF pilots

As expected, watchmakers focused on creating some of the world's most reliable and accurate pilot watches. However, these timepieces required secure straps to function effectively. Nylon Straps played a crucial role in providing dependable 'rapid wear' straps for these early World War II watches.

Post-World War II

The conclusion of World War II, with Europe's conflict ending in May 1945 and Japan's surrender in August, led to a dramatic decrease in the need for military timepieces and watch straps.

With the exception of the Korean War, the demand for military watch straps suffered a significant downturn in military contract business. Occasional sales to former service members offered minimal support to scale productions

1973 - The Rolex 5513 "MILSUB"

The 1970s marked a new era of underwater exploration as well as a need for dependable Nylon straps. To meet the rigorous demands of deep-sea diving, the Royal Navy partnered with Rolex to develop a robust timepiece. This collaboration birthed the iconic Rolex 5513 "MILSUB".

In a perfect match, an 'Admiralty Grey' strap was supplied the Royal Navy with its revolutionary heat-welded High-Density nylon straps to complement these exceptional watches. Thus the iconic bond between Admiralty Grey High-Density nylon strap became inevitably linked.

What is a NATO strap?

Due to its NSN (NATO Stock Number) and G10 model reference listed on Military Order Request Form G10, the original Admiralty Grey is widely recognized as the quintessential 'NATO Strap'

As a result the term 'NATO Strap' has since become a generic descriptor for all nylon watch straps, overshadowing the 'Admiralty Grey' military watch strap original design.

UK Ministry of Defence Specifications

What Sets Phoenix Straps Apart?

Proprietary Materials

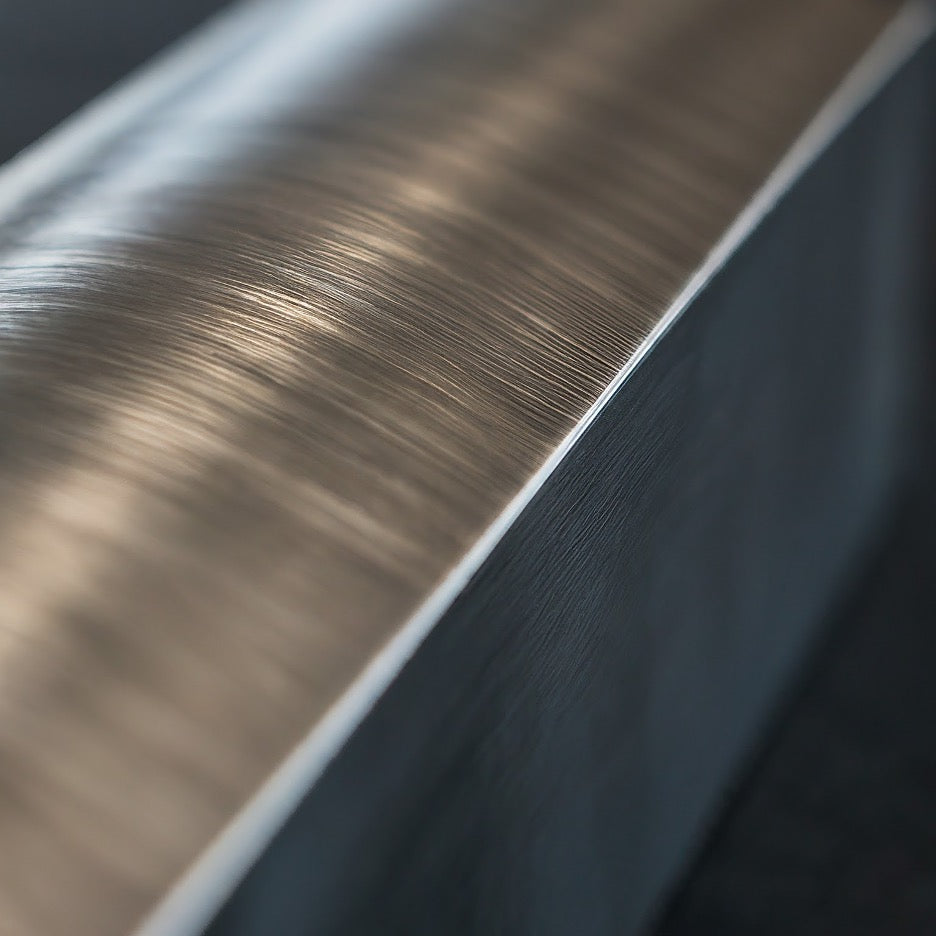

Leveraging public records from Britain's Ministry of Defence, we have been able to create the original MOD strap with a High-Density weave.

Our material is weaved ensuring the highest level of quality and comfortability that manufacturing has to offer.

Heat Welded Technology

This 'engineering' project was no easy feat. Specialized tooling for heat-welding, is required to create a "seamless" design (yes, pun intended). Unlike most other watch strap manufacturers, our straps are stitch-free, ensuring an elegant look.

With Heat-Welding tools are our expert craftsmen who ensure that each edge is heat sealed properly. This level of craftmanship ensures that your watch strap will last decades.